The GU10 spin riveting machine is a non-standard automated riveting device specially designed for the production of GU10 lamps, which is mainly used for spin riveting and fixing the pins (electrode pins) of the GU10 lamp cap and the lamp holder assembly.This GU10 Pin Spin Riveting Machine automatically completes the processes of pin feeding, spin riveting and blanking. The feeding method of the lamp cup can be selected as manual or automatic feeding according to requirements.It can be compatible with both glass and plastic lamp cups.

ModelNo. :

LED-GU1200Capacity :

1200-1800PCS/HOperating Personnel :

0-1perscompliance rate :

>95%Power :

2KW

All of our equipment lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1.Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

1.Main Machine: 1 unit

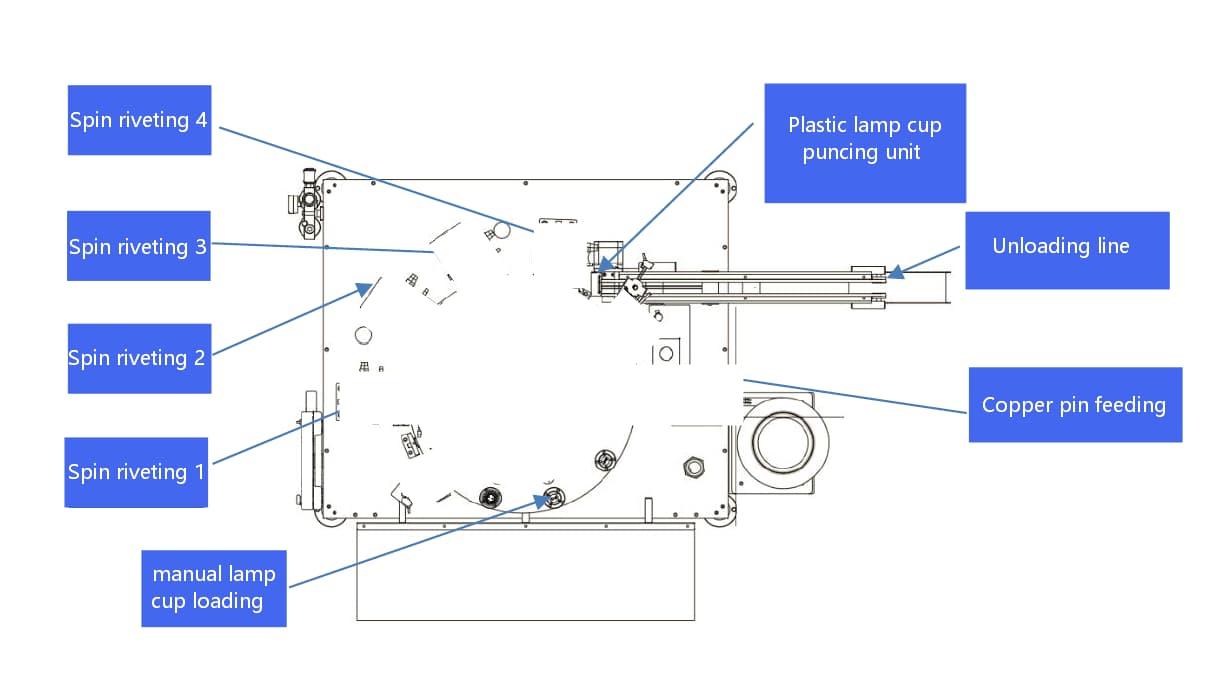

Layout diagram of GU10 lamp cup copper pin spin riveting machine

| Equipment name | GU10 Spin Riveting Machine |

| Material | High strength aluminum, steel |

| Function | For spin riveting and fixing the pins (electrode pins) of the GU10 lamp cap and the lamp holder assembly. |

| Applicable product size | GU10 lamp cups |

| Operation mode | Handle and touch screen |

| Equipment power | 2 KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment air pressure | 0.5-0.8mpa |

| Equipment model | LED-GU1200 |

| Equipment weight | 600 KG |

| Equipment size | 1.5*1.2*1.5M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 1200-1800 pcs/h |

| Apply product | GU10 series lamp cups |

| MOQ | 1PCS |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

FAQ

1. What types of LED light source boards can this machine insert?

It supports round, square, strip-type, panel-type, and customized LED boards.

2. Can the machine integrate with an existing production line?

Yes, Our technical team can also assess the specific conditions of your production line (such as equipment models and production processes),

and make adjustments based on actual situations to ensure seamless coordination with your existing production processes.

3. Will the glass lamp cup be easily cracked during the GU10 lamp cup spin riveting process?

Our equipment will control the spin riveting pressure and adjust the fixture positioning accuracy according to the characteristics of the glass material. Compared with the pressure out-of-control in manual riveting,

the automated equipment can greatly reduce the risk of cracking.

4. What conditions are considered qualified? What is the qualification rate?

Copper pins shall not loosen to the extent of rotation after riveting; no glass damage.

Qualification rate > 95%.

5. What are the main benefits compared to manual insertion?

Higher efficiency, lower labor cost, consistent insertion quality, fewer errors, and a stable automated workflow.

leave a message

Scan to Wechat/Whatsapp :