Full-Automatic 5mm Laparoscopic Trocar Assembly Line

A laparoscopic trocar automatic assembly line is an integrated intelligent manufacturing system designed for the automated assembly of all core components of laparoscopic trocars. It integrates automated feeding, high-precision assembly, in-line testing, finished product sorting, and data traceability functions.This 5mm laparoscopic trocar production line completes a full set of processes, including automatic outer sheath feeding, automated assembly, seal ring feeding and assembly, air injection valve feeding and assembly, rear cover feeding and assembly, and finished product unloading.It is widely applied in professional medical trocar manufacturers, comprehensive minimally invasive surgical instrument production bases, medical device R&D and pilot test institutions, and proprietary production workshops of large medical groups.

ModelNo. :

Synrit-LT5Capacity :

800PCS/HOperating Personnel :

1 perscompliance rate :

>98%compatible :

5mm Laparoscopic TrocarAll of our automatic laparoscopic trocar assembly lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

This full-automatic 5mm laparoscopic trocar assembly line completes a full set of processes, including automatic outer sheath feeding, automated assembly, seal ring feeding and assembly, air injection valve feeding and assembly, rear cover feeding and assembly, and finished product unloading.

1.Assembly Machine :1 Unit

2.Special-Purpose Tooling : 1 Set

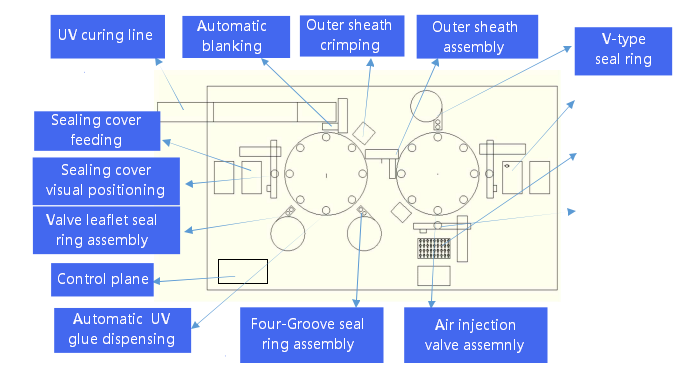

Layout Diagram of laparoscopic trocar automatic assembly line

Product Paramenters

| Equipment name | 5mm Laparoscopic Trocar Assembly Line |

| Material | High strength aluminum, steel |

| Function | This production line realizes the automated assembly process of 5mm Laparoscopic Trocar |

| Applicable product size | Outer diameter of cannula: 5mm , |

| Inner diameter of cannula: 4.2-4.5mm, | |

| Working length (effective insertion part of cannula into abdominal cavity): 100mm, 150mm | |

| Operation mode | Handle and touch screen |

| Equipment power | 8KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment model | Synrit-LT5 |

| Equipment size | 2*1.2*1.4M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 800 pcs/h |

| Apply product | 5mm Laparoscopic Trocar |

| MOQ | 1pcs |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

FAQ

4.Q: What automatic testing methods does the production line have for the key quality indicators of trocars?

A: For key indicators such as air tightness and component assembly alignment, the production line is equipped with an automatic air tightness tester and a 3D visual alignment detection module to ensure product quality.

5.Q: What professional skills are required for daily operation and maintenance? Is operation and maintenance training provided?

A: Only basic equipment operation and electrical knowledge are required for daily operation and maintenance, and no professional medical device qualifications are needed. We will provide customers with free training (including equipment operation, basic maintenance and troubleshooting), as well as paper and electronic operation manuals to ensure that operators can quickly get started with the equipment.

leave a message

Scan to Wechat/Whatsapp :