The GU10 automatic assembly line is a complete set of intelligent manufacturing equipment designed for the large-scale and automated production of GU10 lamps.

This production line realizes automatic assembly processes,such as automatic gluing, automatic inner sleeve installation, automatic testing, automatic riveting, automatic lens gluing, and automatic lens installation. It can be matched with supporting equipment such as laser marking machines, aging test machines, and box packing machines to expand production process links and meet the customized production needs of different customers.

ModelNo. :

LED-GU2000Capacity :

1500-2000PCS/HOperating Personnel :

0-5 perscompliance rate :

>98%Power :

8KWcompatible :

Full range of GU10 productsAll of our GU10 automatic assembly lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

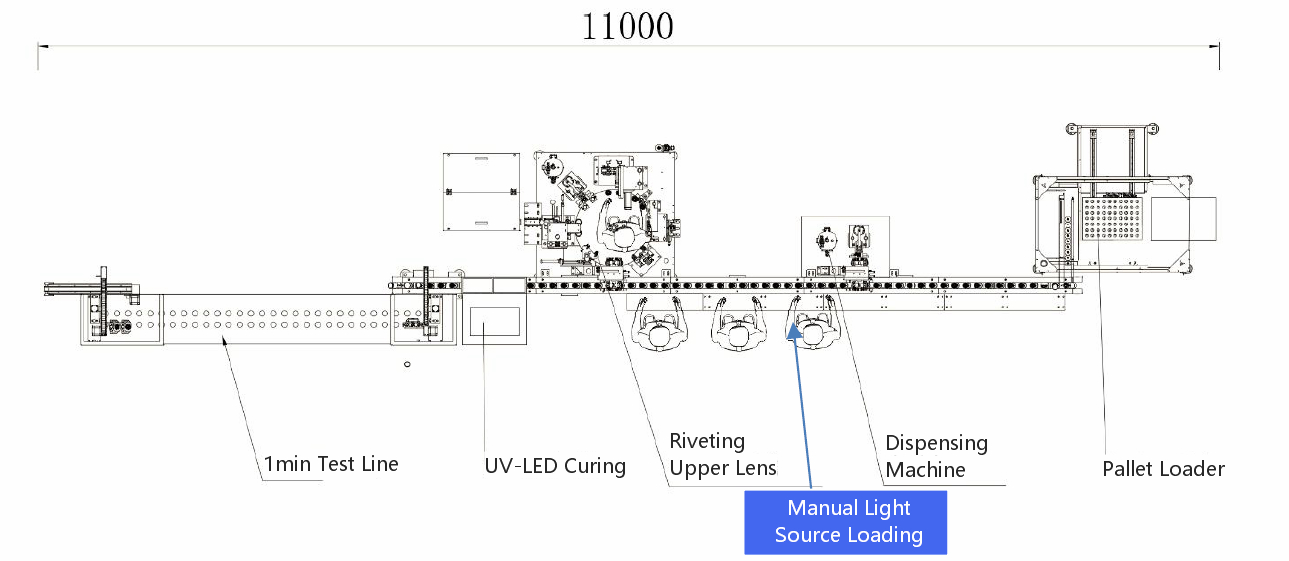

Layout diagram of GU10 automatic assembly line

Compatibility Notes

This production line is compatible with the full range of GU10 products.

Product Paramenters

| Equipment name | GU10 Automatic Assembly Line |

| Material | High strength aluminum, steel |

| Function | This production line realizes the automated assembly process of GU10 products. |

| Applicable product size | Diameter: 50mm,Height: 55mm-60mm |

| Operation mode | Handle and touch screen |

| Equipment power | 8KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment model | LED-GU2000 |

| Equipment size | 11*1.3*1.5M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 1500-2000 pcs/h |

| Apply product | Full range of GU10 |

| MOQ | 1pcs |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

Application Scenario

| Application Scenario | Core Customers | Core Customer Pain Points | Equipment Configuration Focus |

| Scenario 1: Mass Production Upgrade for Small and Medium-sized LED Lighting Enterprises | Small and medium-sized manufacturers with a monthly production capacity of 50,000-200,000 units, focusing on GU10 as their flagship product | High reliance on labor, difficulty in recruiting workers, high defect rate (5%-10%), and production capacity unable to keep up with order growth | High cost-effectiveness, full-process automation (covering loading-assembly-curing-testing), and easy operation |

| Scenario 2: Flexible Production Line Construction for Large Lighting Enterprises | Leading enterprises with a monthly production capacity of over 200,000 units and a rich product line (including the full range of GU10 and other spotlights) | Slow switching between multi-specification products, poor production line compatibility, difficulty in tracking production data, and need to connect to MES systems | Strong compatibility (supports the full range of GU10), quick model changeover, intelligent management, and MES system integration capability |

| Scenario 3: Customized GU10 Production for Cross-border E-commerce | Cross-border e-commerce enterprises focusing on overseas markets (Europe, America, Southeast Asia), which need to customize GU10 parameters (power, light color) according to customer requirements | Small order batches, high demand for customization, short delivery cycles, and strict compliance with overseas certifications (CE, UL) | Flexible adaptation to small-batch production, adjustable parameters, and enhanced quality inspection (compliant with overseas certification standards) |

| Scenario 4: Optical Component Niche Fields (Smart Lighting/Auto Lighting) |

Specialized enterprises producing smart GU10 (with sensors, dimming functions) and automotive auxiliary GU10 spotlights | High requirements for assembly precision (stable optical parameters), and need to integrate special processes (sensor welding, dimming testing) | High-precision visual positioning, capability to integrate special processes (e.g., sensor assembly, function testing), and high stability |

FAQ

1. What materials of GU10 products can this production line be compatible with?

It is compatible with the full range of GU10 products such as plastic, metal, and glass types.

2. Can the machine integrate with an existing production line?

Yes, Our technical team can also assess the specific conditions of your production line (such as equipment models and production processes),

and make adjustments based on actual situations to ensure seamless coordination with your existing production processes.

3. How accurate is the insertion system?

With servo control + CCD vision correction, accuracy reaches ±0.05 mm.

4. Is customization available?

Yes. It can be customized according to your product specifications and production requirements.

5. What is the yield rate of GU10 products produced by automated manufacturing?

The yield rate can reach more than 98%.

leave a message

Scan to Wechat/Whatsapp :