Full-Automatic Gas Injection Valve Assembly Machine for Trocars

ModelNo. :

Synrit-A1Operating Personnel :

0 perscompliance rate :

>98%Power :

2KWSize :

0.8*0.7*1.4MAll of our equipment lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

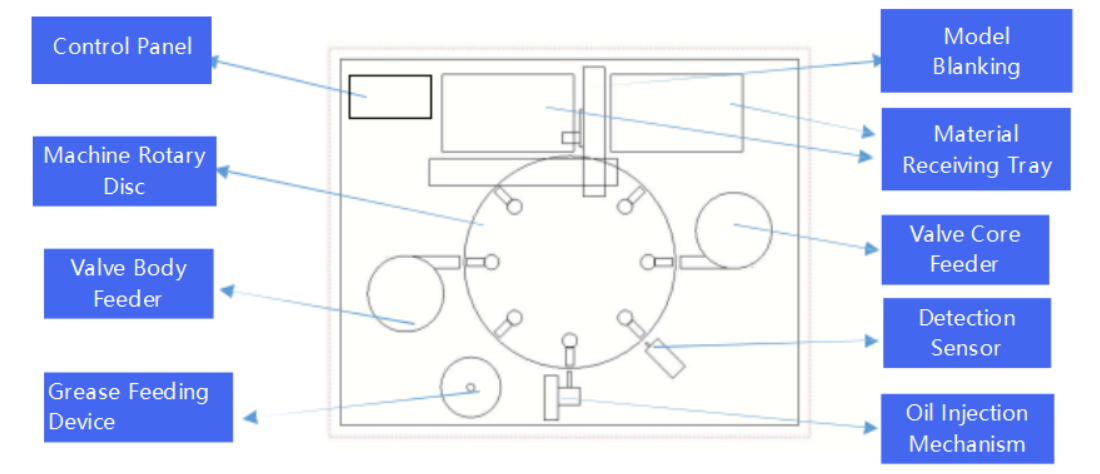

Process Description

This fully-automatic gas injection valve assembly machine completes a full set of processes, including precise feeding, positioning, oiling, press-fitting, inspection and finished product unloading of all components.

1.Assembly Machine :1 Unit

2.Special-Purpose Tooling : 1 Set

Product Paramenters

| Equipment name | Gas Injection Valve Assembly Machine |

| Material | High strength aluminum, steel |

| Function | This production line realizes the automated assembly process of Gas Injection Valve |

| Applicable product size | The outer diameter is generally 8–10 mm |

| Operation mode | Handle and touch screen |

| Equipment power | 2KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment model | Synrit-A1 |

| Equipment size | 0.8*0.7*1.4M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 800 pcs/h |

| Apply product | Gas Injection Valve |

| MOQ | 1pcs |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

VIDEO

FAQ

1. Can the equipment's production capacity match the takt time requirements of our production line?

The standard production capacity of the equipment is 800 pieces/hour (adjustable according to the customer's actual product specifications), and it supports 24-hour continuous operation. By selecting the optional dual-station feeding module, the production capacity can be increased by 30%–50%, which is fully compatible with the takt time requirements of medium and large-scale medical device production lines.

2. What skills do operators need to possess?

Operators do not need professional programming foundation. They can complete parameter setting, production start-stop and other operations through the touch screen visual interface.

3. Do you provide training services?

We provide free on-site training, including equipment operation, daily maintenance and troubleshooting of common faults, ensuring that operators can be trained to work independently within 1–2 days.

4. What is the level of automation of the equipment? How many operators are required?

The equipment adopts a fully automated unattended design, and only 1 operator is needed to be responsible for raw material replenishment, finished product collection and daily equipment inspection. The entire process of feeding, assembly, testing and unloading requires no manual intervention, which greatly reduces labor costs and human error rates.

5. How long is the warranty period of the equipment? What should I do if a malfunction occurs during the warranty period?

The equipment has a 12-month warranty for the whole machine, and core components (servo motors, vision systems, air tightness testers) have a 24-month warranty. In case of non-human-caused malfunctions during the warranty period, we promise to respond within 2 hours and arrange engineers to provide on-site maintenance within 24 hours, with free replacement of faulty components.

leave a message

Scan to Wechat/Whatsapp :