ModelNo. :

Synrit-DP1Capacity :

>600PCS/HOperating Personnel :

6-9 perscompliance rate :

>98%Power :

15KWcompatible :

595×595mm to 620×620mmAll of our panel light automatic assembly lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

Product Description

Compatibility Notes

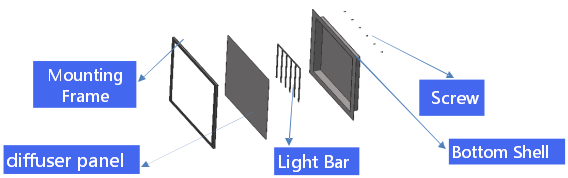

This direct-lit panel light automatic assembly system is compatible with direct-lit panel lights with external dimensions ranging from 595*595 to 620*620.

Product Paramenters

| Equipment name | Direct-lit Panel Lights Assembly Line |

| Material | High strength aluminum, steel |

| Function | It enables integrated manufacturing of direct-lit panel lights, covering the entire process from core component loading to finished product inspection and unloading. |

| Applicable product size | 595*595 |

| Operation mode | Handle and touch screen |

| Equipment power | 15KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment model | Synrit-DP1 |

| Equipment size | 24*4.5*1.4M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 600-700 pcs/h |

| Apply product | Product dimensions ranging from 595×595 to 620×620 |

| MOQ | 1pcs |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

FAQ

1.What specifications of panel lights can this assembly line be adapted to?

leave a message

Scan to Wechat/Whatsapp :