The automatic light source board insertion machine is advanced automated equipment designed for high-efficiency and high-precision insertion of electronic components onto LED light source boards and LED modules. This light source board insertion machine handles processes including automatic feeding of light source boards, insertion of safety resistors, wire insertion, electrolytic capacitor insertion, and automatic blanking. It is widely used in LED lighting manufacturing, including LED bulb light boards, panel lights, strip lights, linear lights, and customized LED modules.

ModelNo. :

Synrit-S1Capacity :

1500-1800PCS/HOperating Personnel :

0.5-1 perscompliance rate :

>98%Power :

2KWSize :

L2400*W1700*H2200(mm)All of our equipment lines are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

We currently have mature and stable equipment available for sale, including GU10 light source board insertion machines, A-bulb light source board insertion machines, T-bulb light source board insertion machines, and Filament Lamp light source board insertion machines.We can customize the equipment according to the size of the light source board, and some sizes are compatible with each other. We can also adjust the output capacity and price based on your specific requirements. Our commitment is to produce the most suitable equipment for your needs.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

Equipment Configuration

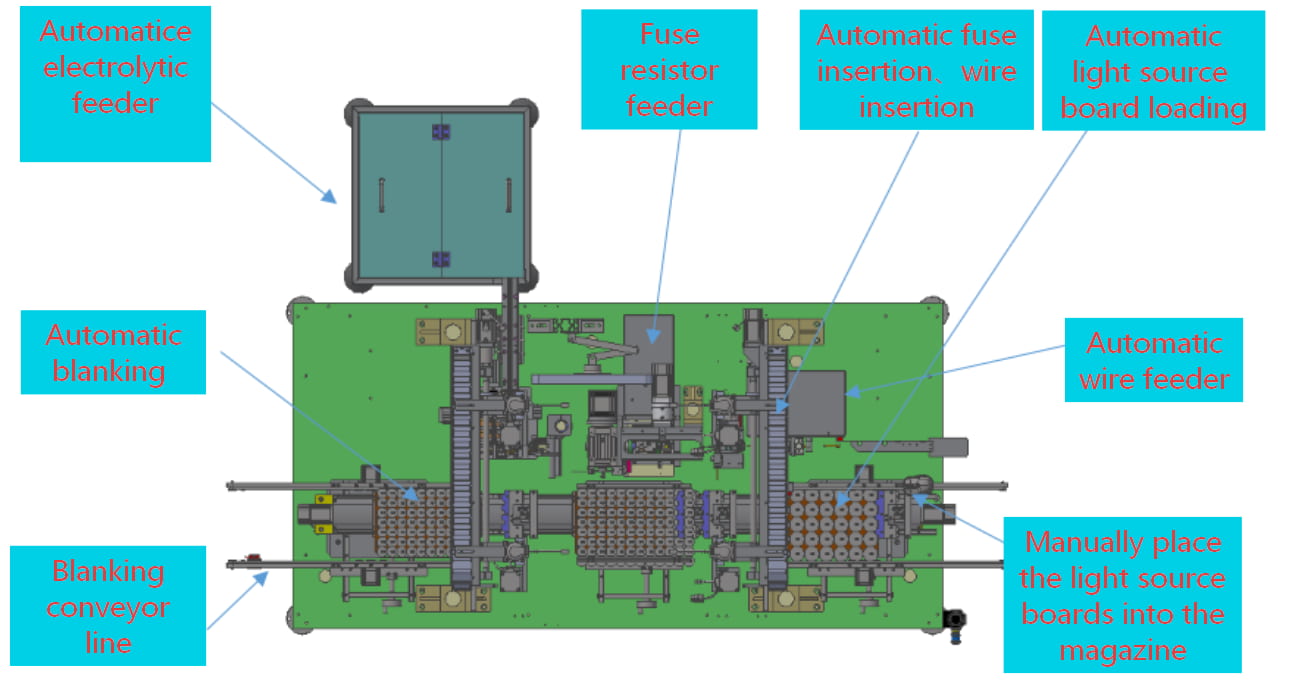

Layout diagram of fully automatic light source board insertion machine

Compatibility Notes

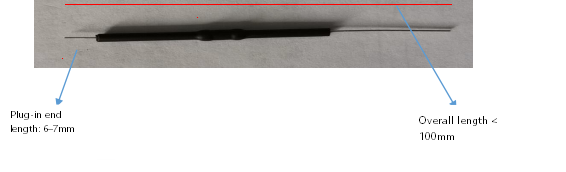

1.Fuse: Total length less than: 100mm, the distance from the heat shrinkable sleeve to both ends of the fuse is greater than: 7mm, and the distance from the resistor to both ends of the fuse is greater than: 15mm

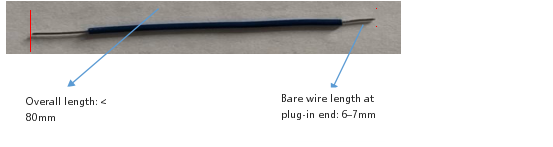

2.The wire is a single-strand hard wire with rigid PVC insulation. The total stripping length is less than 80mm, and the stripping length at both ends is less than 10mm.

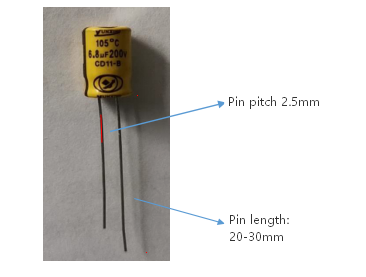

3.Electrolytic capacitor: Pin pitch 2.5mm, Pin length: 20-30mm

4.Light Source Board Size:

| Equipment name | Light Source Board Insertion Machine |

| Material | High strength aluminum, steel |

| Function | This equipment realizes the full-process insertion of light source boards. |

| Applicable product size | Length: 280-380 mm,Width: 170-280 mm |

| Operation mode | Handle and touch screen |

| Equipment power | 2 KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment air pressure | 0.5-0.8mpa |

| Equipment model | Synrit-S1 |

| Equipment weight | 600 KG |

| Equipment size | 2.4*1.7*2.2M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 1500-1800 pcs/h |

| Apply product | DOB light source board |

| MOQ | 1PCS |

Equipment Component Configuration List

| Item | Brand | Remarks |

|---|---|---|

| Guide Rail & Slider | HIWIN, AIR TAC | Genuine |

| Pneumatic Components | AIR TAC | Genuine |

| Motion Controller | SYNRIT | Genuine |

| HMI | WEINVIEW, DALTA | Genuine |

| Relay | OMRON | Genuine |

| Switching Power | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | JSCC | Genuine |

| Servo Motor | KOSSI/HCFA | Genuine |

| Stepper Motor | RUI TE | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic/Equiv. | Genuine |

| Magnetic Switch | AIR TAC | Genuine |

Video

Application Cases

FAQ

1. What types of LED light source boards can this machine insert?

It supports round, square, strip-type, panel-type, and customized LED boards.

2. Can the machine integrate with an existing production line?

Yes, Our technical team can also assess the specific conditions of your production line (such as equipment models and production processes),

and make adjustments based on actual situations to ensure seamless coordination with your existing production processes.

3. How accurate is the insertion system?

With servo control + CCD vision correction, accuracy reaches ±0.05 mm.

4. Is customization available?

Yes. The feeding system, insertion head, PCB dimensions and software can be customized according to your product specifications and production requirements.

5. What are the main benefits compared to manual insertion?

Higher efficiency, lower labor cost, consistent insertion quality, fewer errors, and a stable automated workflow.

leave a message

Scan to Wechat/Whatsapp :