This automatic assembly machine for laparoscopic Veress needles is capable of completing the full-process automated operation of feeding, positioning, press-fitting, assembling and testing for core components (including needle outer tubes, springs, stoppers, two-way valves, handles, etc.). It can realize 24-hour continuous operation. Compared with manual assembly, it can significantly improve the production capacity per unit time, reduce the dependence on skilled assembly workers, and cut down the long-term labor management and training costs. It is especially suitable for large-scale mass production scenarios.

ModelNo. :

Synrit-V1Capacity :

600PCS/HOperating Personnel :

1 perscompliance rate :

>98%Power :

4KWSize :

3.5*1.8*1.8Mcompatible :

110/130mmAll of our veress needle assembly equipment are compatible with non-standard customization. We can tailor-make exclusive automation solutions based on the client’s production line scale, product processes and industry compliance criteria.

Features

1. Higher efficiency

2.Lower labor cost

3.Consistent insertion quality

4.Fewer errors

5.Stable automated workflow

Process Description

The fully automated assembly process for disposable laparoscopic Veress needles consists of continuous procedures including automatic feeding, precision pressing, comprehensive inspection (dimension/air tightness/functionality) and sterile unloading & packaging, all carried out in a Class 8 cleanroom environment, to produce finished Veress needles that comply with the YY/T 0285 standard and enable full batch traceability.

1.Automatic Assembly of Laparoscopic Veress Needle:1 Unit

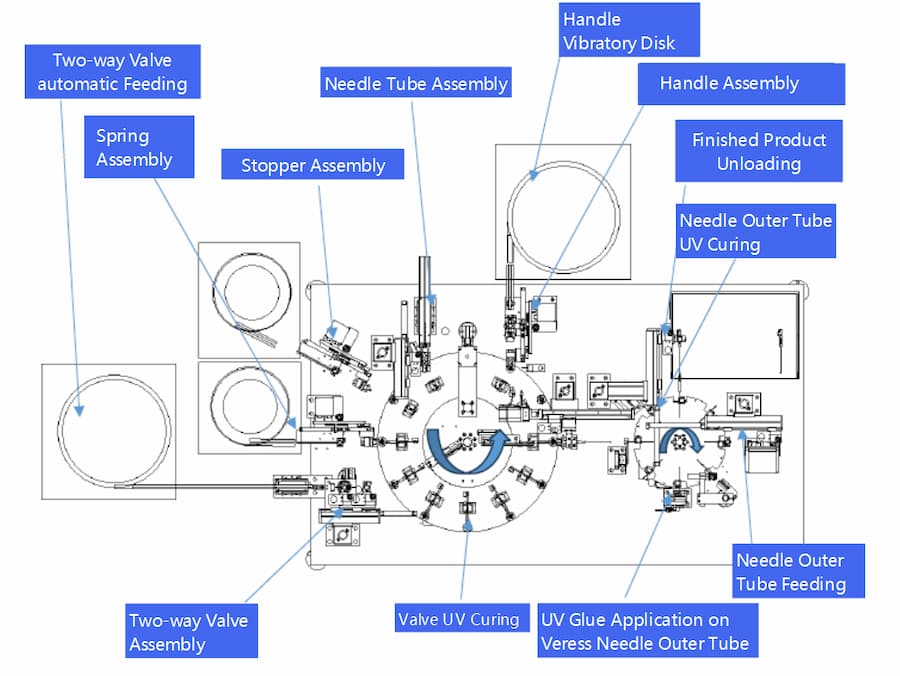

Layout of the fully automatic veress needle assembly equipment

Product Parameters

| Equipment name | Laparoscopic Veress Needle Automatic Assembly Machine |

| Material | High strength aluminum, steel |

| Function | This production line realizes the automated assembly process of Veress Needle |

| Applicable product size | Length: 130 mm |

| Operation mode | Handle and touch screen |

| Equipment power | 4KW |

| Equipment Voltage AC | 220V 50Hz |

| Equipment model | Synrit-V1 |

| Equipment size | 3.5*1.8*1.8M |

| Colour | Industrial white |

| Shape | Class cubes |

| Production speed | 600 pcs/h |

| Apply product | Veress Needle |

| MOQ | 1pcs |

Equipment Component Configuration List

| Item | Brand | Remarks |

| Guide Rail, Slider | Taiwan Hiwin/Airtac | Genuine |

| Pneumatic Components | AIRTAC/SMC | Genuine |

| PLC | Delta Electronics | Genuine |

| HMI | Delta Electronics | Genuine |

| Relay | Omron | Genuine |

| Switching Power Supply | DALTA, MEANWELL | Genuine |

| Asynchronous Motor | Jingyan | Genuine |

| Indexer | Shandong University Ruihua | Genuine |

| Servo Motor | Delta Electronics/Mitsukawa | Genuine |

| Stepper Motor | XFY | Genuine |

| Frequency Inverter | Delta Electronics | Genuine |

| Encoder | Omron | Genuine |

| Bearing | NSK, HRB | Genuine |

| Sensor | Panasonic | Genuine |

| Magnetic Switch | AIRTAC | Genuine |

FAQ

1. Can the Veress needles produced by this assembly machine meet the requirements of medical device industry standards?

2. Can the assembly machine be compatible with Veress needles of different specifications?

Yes. The equipment adopts a modular fixture design and is compatible with Veress needles with a length range of 110/130 mm.

3. The air tightness of Veress needles directly affects surgical safety. Can the equipment complete air tightness testing during the assembly process?

Yes. The equipment is integrated with a negative pressure air tightness testing module. After assembly, a negative pressure of -0.08 MPa is applied to the inner cavity of the Veress needle. A product is deemed qualified if the leakage rate is ≤ 1 Pa·m³/s. Test data is automatically uploaded to the system, which supports production batch traceability and ensures that every Veress needle is free from leakage risks.

4. What qualifications are required for the operators?

Operators are not required to have a professional background in medical devices, but only need to master basic equipment operation knowledge.

5. Do you provide professional training services?

We provide free on-site training services covering equipment parameter setting, production process start-stop, daily cleaning and maintenance, and troubleshooting of common faults, ensuring that operators can work independently within 1–2 days.

leave a message

Scan to Wechat/Whatsapp :